How to replace a fuel pump at home? Sounds intimidating, right? But with the right tools and a little patience, it’s totally doable. This guide walks you through every step, from safely disconnecting the battery to post-installation checks, making sure you’re confident enough to tackle this DIY project. We’ll cover everything from locating that pesky pump to troubleshooting any hiccups along the way.

Get ready to save some serious cash and learn a new skill!

Replacing your fuel pump can seem daunting, but this guide breaks it down into manageable steps. We’ll cover safety precautions, essential tools, locating the pump in various car models, the removal and installation processes, and post-installation checks. We even include a troubleshooting section to help you handle any unexpected issues. So grab your wrench, and let’s get started!

Safety Precautions

Replacing a fuel pump is a serious undertaking that requires careful attention to safety. Failing to prioritize safety can lead to injury, fire, or even death. This section Artikels crucial safety measures to ensure a successful and hazard-free repair.This job involves working with flammable fuel and potentially explosive vapors. Improper handling can have dire consequences. Therefore, the following steps are absolutely critical.

Necessary Safety Equipment

Appropriate safety equipment is paramount for this task. This isn’t a job for your everyday toolbox. You need specific gear to protect yourself from potential hazards.

- Eye protection: Safety glasses or a face shield are essential to protect your eyes from splashing fuel or debris.

- Gloves: Chemical-resistant gloves are crucial to prevent skin contact with fuel and other potentially harmful substances.

- Clothing: Wear long sleeves and pants made of a non-flammable material to protect your skin from burns or fuel spills.

- Closed-toe shoes: Protect your feet from falling objects or spills.

- Jack stands: Never work under a vehicle supported only by a jack. Use jack stands for stability and safety.

- Fire extinguisher: A Class B fire extinguisher (suitable for flammable liquids) should be readily available.

Disconnecting the Battery

Before beginning any work near the fuel system, disconnecting the battery is mandatory. This prevents accidental sparks that could ignite fuel vapors.

- Locate the negative (-) battery terminal.

- Use a wrench to loosen and remove the negative cable clamp.

- Set the cable aside, away from the battery and any metal parts of the vehicle.

- Only after completing the repair, reconnect the negative cable first, then the positive cable.

Safe Fuel Handling Procedures

Fuel is highly flammable and should be handled with extreme caution. Spills should be avoided at all costs.

- Work in a well-ventilated area to prevent the buildup of flammable vapors.

- Use absorbent materials, such as rags or kitty litter, to immediately clean up any fuel spills. Dispose of contaminated materials properly.

- Never smoke or use open flames near the fuel system.

- If you need to drain fuel from the lines, do so carefully into a properly sealed container designed for fuel storage.

- Avoid prolonged skin contact with fuel. Wash any affected areas thoroughly with soap and water.

Potential Hazards and Mitigation

Several hazards exist when replacing a fuel pump. Understanding these hazards and implementing preventative measures is crucial for a safe repair.

- Fuel fire: Always work in a well-ventilated area and use proper safety equipment to minimize the risk of fire. Keep a fire extinguisher handy.

- Fuel inhalation: Fuel vapors can cause dizziness, headaches, and nausea. Work in a well-ventilated area and use a respirator if necessary.

- Burns: Hot fuel lines or components can cause burns. Allow components to cool before handling.

- Injury from tools: Use caution when working with tools and wear appropriate safety equipment to prevent injury.

- Vehicle collapse: Always use jack stands to support the vehicle when working underneath it.

Tools and Materials Required

Replacing your fuel pump is a serious undertaking, requiring precision and the right equipment. Using the wrong tools can lead to damage, injury, or an incomplete repair. This section Artikels the essential tools and materials you’ll need to complete the job safely and effectively. Remember, always consult your vehicle’s repair manual for specific instructions and torque specifications.

Gathering all the necessary tools beforehand saves time and frustration during the repair process. Having everything readily available minimizes interruptions and allows for a smoother workflow. This will also help you avoid costly mistakes.

Essential Tools

The following table lists the essential tools, their quantities, and potential alternatives. It’s crucial to use tools in good working condition to prevent accidents or inaccurate work.

So, you’re thinking about tackling a fuel pump replacement yourself? It’s a pretty involved job, requiring specialized tools and a decent understanding of your car’s fuel system. Before you dive into that, though, you might want to check out the cost of something a little less intense, like a tire rotation – maybe you should just get your tires rotated at Firestone first; you can check prices here: Tire rotation cost at Firestone.

Then, if you’ve still got the mechanical itch, you can get back to that fuel pump. Just remember safety first!

| Tool | Quantity | Alternative | Importance |

|---|---|---|---|

| Socket Wrench Set (Metric or SAE, depending on your vehicle) | 1 set | Adjustable wrench (less precise) | Needed for removing and installing various bolts and nuts. A complete set ensures you have the right size for every fastener. |

| Ratchet | 1 | Combination wrench (slower) | Provides efficient turning of sockets. A good quality ratchet will make the job easier. |

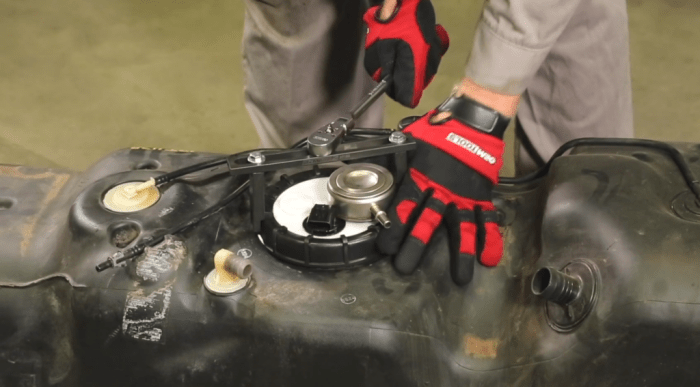

| Fuel Pump Removal Tool (Specific to your vehicle’s make and model) | 1 | DIY tool (requires fabrication skills and knowledge of fuel pump design) | Often necessary to safely remove the fuel pump from the tank. Using an improper tool may damage the pump or tank. |

| Torque Wrench | 1 | None (use caution and feel) | Crucial for tightening bolts to the manufacturer’s specified torque. Over-tightening can strip threads, while under-tightening can lead to leaks. |

| Jack and Jack Stands | 1 jack, 2 jack stands | Vehicle lift (if available) | Essential for safe access to the fuel pump. Never work under a vehicle supported only by a jack. |

| Wrenches (various sizes) | Assorted | Socket wrench set | Useful for accessing bolts and nuts in tight spaces. Having a variety of sizes ensures you have the right fit. |

| Screwdrivers (Phillips and Flathead) | Assorted sizes | None (specific to your vehicle) | May be needed for removing access panels or other components. |

| Safety Glasses | 1 pair | None (risk of eye injury) | Protect your eyes from debris and fuel. |

| Gloves | 1 pair | None (risk of skin irritation or contamination) | Protect your hands from fuel and sharp edges. |

| Fuel Line Disconnect Tool | 1 | Needle-nose pliers (risky, may damage lines) | Safely disconnects and connects fuel lines without damage or leaks. |

Materials Required

Beyond tools, you’ll need specific materials to ensure a successful fuel pump replacement. Using the correct materials is essential for preventing leaks and ensuring the longevity of the repair.

You will need a new fuel pump, specifically designed for your vehicle’s make, model, and year. Failure to use the correct pump could lead to poor performance or damage to the fuel system. You’ll also need new fuel line clamps and potentially new fuel filter. These should be purchased from a reputable auto parts store to ensure compatibility and quality.

Locating the Fuel Pump: How To Replace A Fuel Pump At Home

Finding your fuel pump might seem daunting, but with a little knowledge and the right tools, it’s totally doable. The location varies wildly depending on the make, model, and year of your car. Some are easily accessible under the rear seat, while others require dropping the fuel tank—a significantly more involved process. This section will guide you through the typical locations and access methods.

The fuel pump is usually located within the fuel tank itself, for safety reasons. This means accessing it often requires working with the fuel system, which necessitates careful attention to safety precautions. Always disconnect the battery’s negative terminal before beginning any work.

Fuel Pump Locations in Various Car Models

The fuel pump’s location isn’t standardized across all vehicles. Some common locations include under the rear seat (common in many sedans), inside the fuel tank (most common), or in the engine bay (less common, usually older models). Identifying the specific location for your car model often requires consulting your vehicle’s repair manual or an online resource like a repair forum dedicated to your specific car.

Accessing the Fuel Pump

Accessing the fuel pump can vary significantly depending on its location. If it’s under the rear seat, you’ll likely need to remove the seat and some interior panels. If it’s inside the fuel tank, you’ll need to lower the tank, which typically involves disconnecting fuel lines, electrical connectors, and possibly the tank straps. This is a more involved process and may require specialized tools.

Accessing the fuel pump from the engine bay, if applicable, is generally easier, often just involving removing some components around the pump itself.

Imagine a scenario where you have a 2005 Honda Civic. The fuel pump is typically located within the fuel tank, requiring you to drop the tank. This would involve disconnecting the fuel lines, electrical connectors, and fuel tank straps before lowering the tank with a jack and jack stands. Then, you can access the fuel pump from the top of the tank.

In contrast, a 1980s Ford pickup truck might have the fuel pump located within the engine bay, making access much simpler.

Typical Appearance of a Fuel Pump

A fuel pump generally looks like a cylindrical or slightly oblong metal canister, sometimes with a plastic top. It typically has several connections: fuel lines (inlet and outlet), electrical connectors, and potentially a pressure regulator or fuel level sensor. The pump itself is usually not visible without removing the surrounding components.

Visualize this: Imagine a metallic cylinder about the size of a large soda can. This cylinder has several tubes coming out of it—these are the fuel lines. You’ll also see a wiring harness connected to it—this provides the power for the pump. There might also be a small sensor attached, which monitors the fuel level in the tank.

Flowchart for Locating the Fuel Pump

This flowchart helps visualize the process of finding your fuel pump. Remember to always consult your vehicle’s repair manual for specific instructions.

Start –> Check Vehicle Repair Manual –> Is the pump under the rear seat? Yes –> Access via seat removal. No –> Is the pump in the fuel tank? Yes –> Drop the fuel tank. No –> Is the pump in the engine bay?

Yes –> Access via engine bay components removal. No –> Consult a mechanic.

Fuel Pump Removal Process

Okay, so you’ve located the fuel pump – congrats! Now comes the slightly more involved part: actually getting it out. This process requires patience and careful attention to detail to avoid damaging anything. Remember, we’re working with fuel here, so safety is paramount. We’ve already covered safety precautions, but it bears repeating: always disconnect the battery’s negative terminal before starting any work.

Removing the fuel pump involves several steps, each crucial for a successful replacement. The process varies slightly depending on your car’s make and model, but the general principles remain the same. The key is to work methodically and carefully, taking your time.

Disconnecting Fuel Lines and Electrical Connectors

Before you even think about touching the fuel pump itself, you need to disconnect everything attached to it. This is where a good set of fuel line disconnect tools comes in handy. These specialized tools help you safely disconnect the fuel lines without damaging the lines or spilling fuel. If you don’t have these tools, use extreme caution to avoid damage.

- Identify the fuel lines: There will be at least two lines – one supplying fuel to the engine (usually a high-pressure line) and one returning fuel to the tank (low-pressure line). Visually inspect the lines; they might be color-coded. Some systems might have additional lines or sensors.

- Release clamps and disconnect lines: Carefully release any clamps securing the fuel lines to the pump. Gently work the lines free from the pump fittings. Have rags ready to soak up any fuel spillage, which is highly flammable. A small amount of fuel might seep out, even with careful disconnection.

- Disconnect electrical connector: Locate the electrical connector plugged into the fuel pump. This connector usually has a locking mechanism; gently but firmly push the release lever (if present) and separate the connector. Take a picture or make a note of the connector orientation for reassembly.

Supporting the Fuel Tank During Removal

The fuel tank can be heavy, and improperly supporting it during fuel pump removal can lead to damage to the tank or surrounding components. This is especially true if you’re working underneath the vehicle.

Imagine this: you’re halfway through the process, the tank shifts unexpectedly, and a critical component gets damaged. That’s a costly mistake you want to avoid.

- Secure the tank: Before you even start disconnecting anything, use jack stands to safely support the vehicle. Then, carefully use a suitable support system (like jack stands or a sturdy strap) to cradle the fuel tank. Avoid placing excessive weight directly on the fuel lines or electrical connectors.

- Consider tank straps: Many vehicles have straps or supports specifically designed to secure the fuel tank. Use these to your advantage; they’ll help prevent the tank from moving during removal.

- Use blocks: If necessary, use blocks of wood or other suitable material to evenly distribute the weight of the fuel tank and prevent it from shifting or tilting.

Removing the Fuel Pump Assembly

With the fuel lines and electrical connector disconnected, and the fuel tank properly supported, you can finally focus on removing the fuel pump itself. This step will vary depending on your vehicle’s design; some fuel pumps are accessed through a hatch in the trunk or under the rear seat, while others require dropping the fuel tank. Refer to your vehicle’s repair manual for specific instructions.

Remember, this is a crucial step and you want to avoid damaging the pump itself or any surrounding components.

- Access the fuel pump: This might involve removing a cover, accessing a hatch, or even dropping the fuel tank (which requires more extensive work and safety precautions). Carefully follow your vehicle’s repair manual.

- Remove retaining ring or bolts: The fuel pump assembly is typically held in place by a retaining ring or a series of bolts. Carefully remove these fasteners, keeping track of their location and order for reassembly.

- Lift out the fuel pump assembly: Once the fasteners are removed, gently lift out the fuel pump assembly. Be mindful of any remaining connections or components that might still be attached.

Installing the New Fuel Pump

Okay, so you’ve wrestled the old fuel pump out. Now it’s time to put the new one in – the reverse of the removal process, but with a little extra care to ensure a leak-free installation. Remember, we’re working with fuel here, so precision is key.The installation process mirrors the removal, but remember to handle the new pump with care to avoid damaging any components.

Pay close attention to the orientation of the electrical connector and the fuel lines. A little patience now will save you headaches later.

Fuel Pump Seating and Connection

Proper seating of the fuel pump is crucial for preventing leaks and ensuring proper function. Start by carefully aligning the pump with its mounting bracket. Gently push it into place, ensuring it sits flush against the mounting surface. You should feel a secure fit; if it feels loose, double-check the alignment. Next, connect the fuel lines.

These lines usually have a quick-connect system, but if not, use clamps to secure them tightly. Make sure the clamps are properly tightened to prevent leaks. Finally, reconnect the electrical connector, making sure it clicks securely into place. A loose connection could lead to electrical issues and potentially damage the pump.

Preventing Leaks During Installation

Leaks are the biggest concern when working with fuel. To prevent them, meticulously inspect all connections for proper seating and tightness. Use new clamps if necessary, ensuring they’re properly tightened and not over-tightened (which could damage the lines). After installation, take some time to visually inspect all connections. Look for any signs of leakage, even small ones.

If you notice any fuel seepage, immediately tighten the connection or replace the clamp. A small leak can quickly become a significant problem. Also, consider using a fuel-safe sealant on any threaded connections to provide an extra layer of protection against leaks.

Installation Checklist

Before starting your car, it’s vital to ensure everything is properly installed and connected. This checklist will help you confirm all steps are correctly completed:

- Fuel pump is correctly seated in the mounting bracket.

- Fuel lines are securely connected and clamped.

- Electrical connector is securely connected.

- All connections have been visually inspected for leaks.

- Fuel tank cap is securely fastened.

- All tools have been safely put away.

Remember, if you have any doubts about any step, consult your vehicle’s repair manual or seek professional help. It’s always better to be safe than sorry when dealing with fuel systems.

Post-Installation Checks

After wrestling that fuel pump into place, the real test begins: making sure everything works flawlessly. A few crucial checks will ensure you didn’t just install a fancy paperweight. These checks are essential for both your safety and the longevity of your vehicle. Ignoring them could lead to further, more expensive repairs down the road.Checking the new fuel pump’s functionality involves a multi-step process, starting with a visual inspection and progressing to more involved tests.

This ensures you’ve addressed all potential problems before hitting the ignition.

So, you’re thinking about tackling a fuel pump replacement yourself? That’s ambitious! While it’s definitely doable, if you’re more into the finer things, maybe you should consider outsourcing the wrenching and instead check out VIP concierge services for Rolls-Royce owners – they probably handle way more complex stuff than a fuel pump. But hey, if you’re determined to DIY, good luck with that fuel pump!

Fuel Leak Inspection, How to replace a fuel pump at home

Thoroughly inspect all connections and the pump itself for any signs of fuel leakage. Look closely at the fuel lines, clamps, and the pump’s mounting area. Even a small leak can be dangerous and create a significant fire hazard. Wipe down any potential leak areas with a clean cloth, and then carefully re-inspect for dampness or fuel residue.

If you find any leaks, immediately tighten any loose connections or replace any damaged components before proceeding. Remember, fuel leaks are not something to take lightly.

Fuel Pressure Testing

A fuel pressure gauge is essential for verifying the pump’s output. This gauge connects to a test port, usually located on the fuel rail. Consult your vehicle’s repair manual for the exact location and procedure. The manual will also specify the correct fuel pressure for your engine. A typical fuel pressure might range from 30 to 60 PSI (pounds per square inch), but this varies greatly depending on the make and model of your car.

If the pressure is too low, it indicates a problem with the pump or another component in the fuel delivery system. If it’s too high, it could indicate a regulator issue. Always refer to your vehicle’s specifications to determine the acceptable pressure range.

Engine Starting and Running Test

Once you’ve confirmed no leaks and the fuel pressure is within the acceptable range, it’s time to start the engine. Listen closely for any unusual noises coming from the fuel pump area. A whining or buzzing sound could indicate a problem with the pump’s motor. Let the engine run for a few minutes, observing for any performance issues like hesitation, sputtering, or stalling.

If the engine runs smoothly and without any problems, the fuel pump installation was likely successful. If you experience any issues, it’s best to double-check your work and potentially seek professional assistance.

Troubleshooting Common Issues

Replacing a fuel pump seems straightforward, but sometimes things don’t go as planned. This section covers common problems you might encounter and how to solve them, saving you time and frustration. Understanding these potential issues beforehand can significantly improve your success rate.

Engine Fails to Start After Fuel Pump Replacement

A non-starting engine after a fuel pump replacement is a common problem, often stemming from simple oversights. Several factors can contribute to this issue. The most frequent culprits are incorrect installation, faulty connections, or overlooked components.

- Improper Installation: The new fuel pump might not be seated correctly, leading to poor fuel flow. Double-check that the pump is firmly secured and aligned with the fuel lines. A slightly misaligned pump can prevent it from functioning properly.

- Faulty Electrical Connections: Loose or corroded connections between the pump and the vehicle’s electrical system will prevent power from reaching the pump. Inspect all wiring for damage, ensuring secure connections. A simple visual inspection may not suffice; use a multimeter to test for continuity and voltage.

- Fuel Line Issues: Damaged or clogged fuel lines can restrict fuel flow, even with a new pump. Check the lines for kinks, cracks, or blockages. If the lines are old or brittle, consider replacing them. Air trapped in the fuel lines can also cause starting problems.

- Fuel Filter Problems: A clogged fuel filter can prevent fuel from reaching the engine, even if the pump is working correctly. A new fuel filter should always be installed during a fuel pump replacement to ensure optimal performance. If this step was skipped, replacing the filter should resolve the problem.

- Relay or Fuse Issues: The fuel pump relay or fuse might be blown or faulty. Check the relay and fuse box for any blown fuses or malfunctioning relays. Replacing these components with new ones might restore power to the pump. A multimeter can be used to check the relay’s continuity and the fuse’s integrity.

Fuel Pump Doesn’t Prime

A fuel pump that doesn’t prime means it isn’t drawing fuel. This can be due to several reasons.

- Air Leaks: Leaks in the fuel lines can introduce air into the system, preventing the pump from priming. Check all fuel line connections carefully for leaks, tightening any loose connections or replacing damaged sections.

- Clogged Fuel Filter: As mentioned previously, a clogged fuel filter restricts fuel flow, hindering the pump’s ability to prime. Replacing the filter should resolve this issue.

- Faulty Fuel Pump: In rare cases, the new fuel pump itself might be defective. If all other checks are negative, consider contacting the supplier for a replacement.

Low Fuel Pressure

Insufficient fuel pressure can lead to poor engine performance or failure to start.

- Pressure Regulator Issues: A faulty fuel pressure regulator can cause low pressure. This component regulates fuel pressure within the system. It may need to be inspected or replaced if suspected.

- Fuel Pump Issues: A weak or malfunctioning fuel pump (even a new one if defective) will deliver low fuel pressure. A fuel pressure gauge can be used to verify the actual pressure. This is often a crucial step in troubleshooting.

Troubleshooting Decision Tree

The following decision tree Artikels a systematic approach to troubleshooting a non-starting engine after fuel pump replacement.

- Check for power at the fuel pump: If no power, check fuses and relay. Replace if necessary. If power is present, proceed to step 2.

- Check fuel lines for leaks and blockages: Repair or replace as needed. If lines are clear, proceed to step 3.

- Check fuel filter: Replace if necessary. If filter is clear, proceed to step 4.

- Verify fuel pump installation: Ensure proper seating and connections. If everything is correct, proceed to step 5.

- Check fuel pressure: If pressure is low, suspect a faulty pump or pressure regulator. Replace as needed.

Epilogue

Replacing your fuel pump yourself is a rewarding experience, saving you money and giving you a deeper understanding of your car’s mechanics. Remember, safety is paramount – always disconnect the battery and handle fuel carefully. By following the steps Artikeld, and referring to the troubleshooting section if needed, you’ll confidently handle this project. Now go forth and conquer that fuel pump!