Cost to upgrade truck suspension for towing? Yeah, that’s a serious question, especially if you’re hauling a serious load. Whether you’re towing a tiny fishing boat or a monster RV, upgrading your truck’s suspension is key to a safe and comfortable ride. This isn’t just about fancy features; it’s about preventing damage to your truck and ensuring everyone’s safety.

We’ll break down the costs, different upgrade types, and whether you should DIY or call in a pro. Get ready to level up your towing game!

This guide dives into the nitty-gritty of upgrading your truck’s suspension for towing. We’ll explore various upgrade options, from simple helper springs to a full-blown air ride system, and discuss the factors influencing the overall cost. We’ll compare DIY versus professional installation, weigh the pros and cons, and help you choose the right upgrade for your specific towing needs and budget.

Think of it as your ultimate towing suspension upgrade survival guide.

Types of Truck Suspension Upgrades for Towing

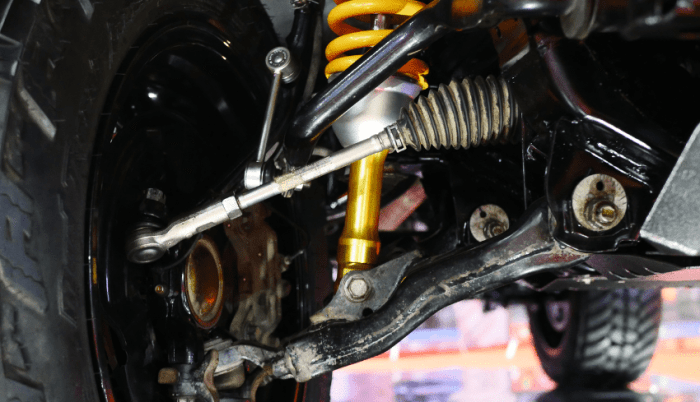

Upgrading your truck’s suspension is crucial for safe and comfortable towing. The right suspension system significantly impacts your truck’s load capacity, handling, and overall ride quality. Choosing the best upgrade depends on your towing needs, the terrain you typically navigate, and your budget. Let’s explore the common options.

Truck Suspension Upgrade Types

The choice of suspension upgrade significantly affects your towing experience. Consider these key differences when deciding which type best suits your needs.

| Type | Description | Pros | Cons |

|---|---|---|---|

| Air Ride | Uses air bags or air springs to support the load. Air pressure can be adjusted to control ride height and stiffness. | Excellent load capacity, adjustable ride height for leveling, superior ride comfort, especially on rough terrain. | Higher initial cost, requires air compressor and maintenance, potential for leaks or component failure. |

| Leaf Spring | Uses a series of steel leaves to support the load. Often found in heavier-duty trucks. | Durable, relatively inexpensive, high load capacity (especially multi-leaf setups). | Harsh ride quality, especially when unloaded, limited adjustability, prone to rust and wear. |

| Coil Spring | Uses coil springs to support the load. Common in lighter-duty trucks. | Generally a smoother ride than leaf springs, relatively inexpensive compared to air ride. | Lower load capacity than leaf springs or air ride, may sag under heavy loads. |

| Helper Springs (Add-on Springs) | Auxiliary springs installed in addition to the existing suspension system to increase load capacity. | Increases load capacity without replacing the entire suspension system, relatively inexpensive. | Can negatively impact ride quality if improperly installed, may not significantly improve ride quality on rough terrain. |

Suspension Type Suitability for Towing Weights and Terrains

This table illustrates how different suspension types perform under various towing conditions. Remember that these are generalizations, and specific performance will depend on the truck, the trailer, and the quality of the upgrade components.

| Suspension Type | Light Towing (<5,000 lbs) | Medium Towing (5,000-10,000 lbs) | Heavy Towing (>10,000 lbs) | Off-Road Capability |

|---|---|---|---|---|

| Air Ride | Excellent | Excellent | Excellent | Good (adjustable height helps navigate obstacles) |

| Leaf Spring | Good | Good | Excellent | Fair (can be harsh on rough terrain) |

| Coil Spring | Good | Fair (may sag) | Poor (likely to sag excessively) | Poor (limited articulation) |

| Helper Springs | Good (improves existing system) | Good (improves existing system) | Fair (may not be sufficient for extremely heavy loads) | Fair (depends on the base suspension system) |

Factors Affecting Upgrade Costs: Cost To Upgrade Truck Suspension For Towing

Upgrading your truck’s suspension for towing isn’t a one-size-fits-all proposition. The final cost depends on a complex interplay of factors, ranging from the type of upgrade you choose to unforeseen mechanical surprises during installation. Understanding these variables is crucial for budgeting effectively. Let’s break down the key cost drivers.Several key factors significantly impact the overall expense of a truck suspension upgrade designed for towing.

These include the cost of parts, labor charges, and the inherent complexity of the installation process itself. The type of upgrade selected will heavily influence these factors, resulting in a wide range of potential costs.

Labor Costs and Parts Costs

Labor costs vary widely depending on your location and the shop’s hourly rate. A simple helper spring installation might take a couple of hours, while a full air ride system could require a full day or more of skilled labor. Parts costs also fluctuate based on brand, quality, and the specific components needed. For example, a basic leaf spring upgrade might cost a few hundred dollars, whereas a high-end air suspension system can easily run into the thousands.

- Basic Helper Spring Install: Expect to pay between $300 and $800, including parts and labor. This range accounts for variations in helper spring types and regional labor rates.

- Upgraded Leaf Spring Pack: A more substantial upgrade, replacing the entire leaf spring pack, could cost anywhere from $800 to $2500, again dependent on the brand and complexity of the installation.

- Air Ride Suspension System: This is the most expensive option, typically ranging from $2500 to $8000 or more, depending on the features and brand. Installation complexity and the need for specialized tools significantly impact this cost.

Cost Variations Based on Truck Make, Model, and Year

The make, model, and year of your truck directly influence the cost of a suspension upgrade. Older trucks may require more extensive modifications, increasing both parts and labor costs. Conversely, newer trucks might have more readily available aftermarket parts, potentially lowering the overall expense. Certain truck brands might also have a more extensive aftermarket support system, leading to potentially lower costs for parts.

For example, a popular model like a Ford F-250 will likely have more readily available and competitively priced parts compared to a less common truck model.

Unforeseen Installation Issues, Cost to upgrade truck suspension for towing

During installation, unforeseen problems can arise, leading to unexpected costs. This might include discovering rusted or damaged components requiring replacement, needing specialized tools not initially anticipated, or encountering unexpected complexities in the vehicle’s design. These unforeseen issues can add hundreds or even thousands of dollars to the final bill. For example, a seemingly simple helper spring installation might uncover severely corroded leaf spring mounts requiring extensive repair or replacement, significantly increasing the total cost.

DIY vs. Professional Installation

Choosing between DIY and professional installation for your truck suspension upgrade is a significant decision impacting both your wallet and the longevity of your truck. The right choice depends on your mechanical aptitude, available time, and risk tolerance. A professional installation offers peace of mind, but DIY can save you money if done correctly.The following table compares the key aspects of DIY versus professional installation, helping you weigh the pros and cons for your specific situation.

So, you’re looking at the cost to upgrade your truck suspension for towing? That can get pricey, depending on how much you’re hauling. But before you drop a ton of cash on suspension, consider other performance upgrades; for example, check out these Cold air intake upgrades for Chevy Silverado to boost your engine’s efficiency. Ultimately, a well-balanced approach to upgrades – addressing both suspension and engine – will improve your towing experience.

DIY vs. Professional Installation Comparison

| DIY | Professional | |

|---|---|---|

| Cost | Lower; only the cost of parts. | Higher; includes labor costs, potentially parts markup. Expect to pay several hundred dollars, potentially exceeding a thousand depending on the complexity of the upgrade. |

| Time Commitment | Significantly longer; potentially several hours to a full day or more, depending on experience and complexity of the upgrade. | Shorter; typically a few hours to a half-day, depending on the shop and the upgrade. |

| Risk of Damage | Higher; potential for incorrect installation, damage to parts, or injury. | Lower; professionals have the expertise and tools to minimize risks. |

| Warranty Considerations | May void manufacturer warranties on parts or the entire truck if improperly installed. | Typically maintains warranties on parts as the installation is performed by a qualified technician. |

| Required Expertise | Requires significant mechanical knowledge, specialized tools, and experience with truck suspension systems. | Requires no expertise from the customer; professionals possess the necessary skills and training. |

Helper Spring Installation Procedure (DIY)

This procedure Artikels a basic helper spring installation. Remember, this is a simplified example and may not apply to all truck models or suspension types. Always consult your vehicle’s service manual for specific instructions and safety precautions. Improper installation can lead to serious damage or injury.Before beginning any work, ensure your truck is safely secured on jack stands and the parking brake is engaged.

Wear appropriate safety gear, including gloves and safety glasses.

- Gather necessary tools and materials: This will include the helper springs themselves, appropriate jack stands, a wrench set, possibly a torque wrench, and potentially a helper to assist with lifting and positioning the springs.

- Locate the attachment points: Identify the correct mounting points on the truck’s axle and suspension system for the helper springs. This will often involve locating existing mounting brackets or holes.

- Secure the helper springs: Carefully attach the helper springs to their designated mounting points, following the manufacturer’s instructions. This may involve bolting, clamping, or other methods.

- Lower the vehicle: Slowly lower the vehicle to the ground, ensuring the helper springs are properly seated and aligned.

- Test and adjust: Test the suspension’s functionality, checking for any unusual noises or behaviors. Make adjustments as needed to ensure proper alignment and function.

Potential Risks and Complications of DIY Installation

DIY installation carries inherent risks. Incorrect installation can lead to a variety of problems, including:

- Improper suspension geometry: Incorrectly installed components can alter the suspension’s geometry, affecting handling, braking, and tire wear. This can lead to unsafe driving conditions.

- Component damage: Improper installation can damage existing suspension components, requiring costly repairs or replacements. For example, forcing parts into place can strip threads or bend metal.

- Safety hazards: Incorrectly installed suspension components can lead to catastrophic failure, potentially causing accidents and injuries.

- Warranty issues: Many manufacturers’ warranties will be voided if modifications are improperly performed. This can leave you with significant repair costs if something goes wrong.

Choosing the Right Upgrade for Specific Towing Needs

Picking the perfect suspension upgrade isn’t just about throwing money at the problem; it’s about matching your towing needs to the right solution. Understanding the weight and type of trailer you’ll be hauling is crucial for selecting a system that provides both safety and a comfortable ride. Ignoring this step can lead to a less-than-ideal towing experience, or worse, safety hazards.Choosing the right suspension upgrade involves careful consideration of several factors, primarily the weight of your trailer and the type of terrain you’ll be navigating.

Heavier trailers and rougher terrain necessitate more robust upgrades than lighter loads and smoother roads. It’s also essential to consider your truck’s payload capacity and Gross Vehicle Weight Rating (GVWR) to avoid overloading the vehicle.

Trailer Weight and Type Influence on Suspension Upgrade Selection

The weight of your trailer is the single most important factor in determining the necessary suspension upgrade. A small utility trailer carrying landscaping supplies requires a far less significant upgrade than a large travel trailer or a heavy-duty boat. The type of trailer also plays a role; a boat trailer, for instance, often requires a suspension system capable of handling the uneven weight distribution inherent in its design.

So, you’re looking at upgrading your truck’s suspension for towing? That cost can really vary, depending on what you need. Before you drop some serious cash, though, you might want to check out this comparison of Ford F-150 vs Chevy Silverado reliability 2025 to see which truck’s stock suspension might better suit your needs and potentially save you some upgrade costs.

Ultimately, choosing the right truck platform will heavily influence the total cost of your towing setup.

For example, towing a small 1,000-pound jon boat might only require an upgrade to heavier-duty shocks and leaf springs, while hauling a 10,000-pound RV would necessitate a complete air-ride suspension system or a heavy-duty leaf spring setup with added helper springs.

Examples of Towing Scenarios and Recommended Upgrades

- Towing a small 1,000 lb jon boat: A modest upgrade like heavier-duty shocks and potentially an upgraded leaf spring pack would likely suffice. This would improve handling and control while mitigating excessive bouncing.

- Towing a 6,000 lb travel trailer: A more substantial upgrade would be needed. Options include a helper spring system to increase the load capacity of the existing leaf springs, or potentially a full air-ride suspension system for optimal load-leveling and a smoother ride, especially on uneven terrain.

- Towing an 8,000 lb RV: For this heavier load, an air-ride suspension system is generally recommended. Air-ride systems provide excellent load-leveling capabilities, crucial for maintaining stability and handling with a heavy RV. They also offer a significantly smoother ride.

Flowchart for Choosing the Right Suspension Upgrade

A simple flowchart can help guide the decision-making process. This flowchart considers towing weight, terrain, and budget.[Imagine a flowchart here. The flowchart would begin with a question: “What is the total towing weight?” This would branch into weight categories (e.g., under 2,000 lbs, 2,000-5,000 lbs, 5,000+ lbs). Each weight category would then branch into terrain considerations (e.g., paved roads only, mixed terrain, off-road).

Each of these would then branch into budget considerations (e.g., low budget, mid-range budget, high budget). Each end point would recommend a specific upgrade type (e.g., upgraded shocks, helper springs, air-ride suspension).]

Payload Capacity and Gross Vehicle Weight Rating (GVWR)

It is absolutely critical to check your truck’s owner’s manual for its payload capacity and GVWR. The payload capacity is the maximum weight the truck can carry (including passengers, cargo, and the tongue weight of the trailer). The GVWR is the maximum weight of the truck and its contents, including the trailer. Exceeding either of these limits can significantly compromise safety, handling, and even lead to damage to your truck’s components.

For example, if your truck has a GVWR of 10,000 lbs and you’re towing an 8,000 lb trailer, you must ensure the truck’s weight, including passengers, cargo, and the trailer’s tongue weight, does not exceed 10,000 lbs.

Maintenance and Lifespan of Upgraded Suspensions

Upgrading your truck’s suspension for towing is a significant investment, and understanding the maintenance needs and lifespan of different systems is crucial for maximizing your return on investment and ensuring safe towing operations. Proper maintenance not only extends the life of your upgraded suspension but also optimizes its performance, leading to a smoother, safer, and more controlled towing experience.

Neglecting maintenance can lead to premature wear, component failure, and potentially dangerous situations on the road.Proper maintenance is key to extending the life and performance of your upgraded suspension system. Different upgrade types have varying lifespans and maintenance requirements, which depend on factors such as driving conditions, towing loads, and the quality of the components. Regular inspections and scheduled maintenance are essential to prevent costly repairs and ensure your truck’s safety.

Lifespan and Maintenance of Common Suspension Upgrades

The lifespan of a suspension upgrade varies significantly depending on the type of upgrade and the frequency of use. For example, a heavy-duty leaf spring setup, known for its durability, might last 10 years or more with proper maintenance, whereas air bags, subjected to more stress and potential punctures, may require replacement or servicing every 3-5 years depending on usage.

Similarly, shocks and struts, regardless of the suspension type, are wear items that generally need replacing every 50,000-100,000 miles, depending on driving conditions and towing loads.

Common Maintenance Tasks and Costs

Regular maintenance is essential for preserving the integrity and longevity of your upgraded suspension. This involves several tasks with varying costs. Prices are estimates and can fluctuate based on location, labor rates, and parts availability.

Here’s a list of common maintenance tasks and their estimated costs:

- Shock Absorber/Strut Replacement: $100-$300 per shock/strut (parts only), plus $50-$150 per hour in labor. This depends heavily on the type of shock and accessibility.

- Air Bag Pressure Checks and Inflation: $0-$50. This is often free if you have an air compressor, but a shop might charge a small fee for a check and inflation.

- Leaf Spring Lubrication: $25-$75. This involves lubricating the spring bushings and shackles to reduce friction and wear.

- Coil Spring Inspection: $25-$50. This usually involves a visual inspection for cracks or damage during a regular service.

- Suspension Component Inspection: $50-$150. This comprehensive check for wear and tear on bushings, ball joints, tie rod ends, etc. is often part of a routine service.

Maintaining Upgraded Suspension for Extended Lifespan

Consistent maintenance significantly impacts the longevity and performance of your upgraded suspension. Following a regular maintenance schedule and addressing issues promptly prevents small problems from escalating into costly repairs.

Key strategies for extending lifespan include:

- Regular Inspections: Visually inspect your suspension components for wear and tear, cracks, leaks, or damage after each long trip or towing job. Look for signs of rust, loose bolts, or unusual noises.

- Scheduled Maintenance: Follow the recommended maintenance schedule for your specific suspension type (detailed below). This might include shock absorber replacements, air bag pressure checks, lubrication, and more.

- Proper Loading: Avoid overloading your truck beyond its rated towing capacity. Overloading puts excessive stress on the suspension, leading to premature wear and tear.

- Careful Driving: Avoid harsh driving maneuvers such as aggressive acceleration, braking, and cornering. Smooth driving reduces stress on the suspension components.

- Environmental Protection: Regularly clean and protect your suspension components from corrosion, especially in areas with harsh weather conditions.

Typical Maintenance Schedule for Various Suspension Upgrade Types

The following table Artikels a typical maintenance schedule. These are estimates, and the actual schedule may vary based on usage and driving conditions. Always consult your suspension system’s manufacturer’s recommendations.

| Suspension Upgrade Type | Shock/Strut Replacement (miles) | Air Bag Pressure Check (months) | Other Maintenance (Frequency) |

|---|---|---|---|

| Heavy-Duty Leaf Springs | 50,000-100,000 | N/A | Lubricate shackles and bushings annually |

| Air Bag Suspension | 50,000-100,000 | Monthly | Inspect air lines and fittings semi-annually |

| Coil Spring Upgrade with Shocks | 50,000-100,000 | N/A | Inspect springs for cracks annually |

End of Discussion

So, upgrading your truck’s suspension for towing? It’s an investment, sure, but one that pays off big time in safety, ride quality, and the peace of mind knowing your truck can handle the load. Remember to factor in all the costs—parts, labor, potential unforeseen issues—and choose the upgrade that best suits your towing needs and budget. Whether you DIY or go pro, do your research, and hit the road with confidence!