Commercial-grade car wash equipment: It’s way more than just soap and water, dude. We’re talking high-pressure systems, automated wonders, and enough cleaning power to make your car gleam like a diamond. This deep dive explores the different types of equipment, from self-serve bays to conveyor systems, covering everything from setup costs to eco-friendly practices. Get ready to become a car wash pro!

This guide breaks down the nitty-gritty of commercial car wash equipment, exploring the various types available, their key components, maintenance needs, and environmental impact. We’ll also cover how to choose the right equipment for your business, ensuring you make a smart investment that maximizes efficiency and profitability. Think of it as your ultimate handbook for dominating the car wash game.

Types of Commercial-grade Car Wash Equipment

Choosing the right commercial car wash equipment is a crucial decision impacting profitability and customer satisfaction. The initial investment, ongoing operational costs, and the type of cleaning offered all depend heavily on the equipment selected. This section details the various types available, highlighting their strengths and weaknesses to aid in informed decision-making.

Self-Service Bays

Self-service bays offer customers a hands-on car washing experience. They typically consist of individual washing stalls equipped with high-pressure wands, soap dispensers, and often, vacuum cleaners.

| Equipment Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Self-Service Bay | Individual stalls with high-pressure wands, soap dispensers, and vacuum cleaners, allowing customers to wash their vehicles themselves. | Lower initial investment compared to automated systems; generates revenue per bay used; attracts a DIY clientele. | Relies on customer effort, potentially leading to inconsistent cleaning; requires regular maintenance of equipment; higher labor costs for cleaning and maintenance. |

In-Bay Automatics

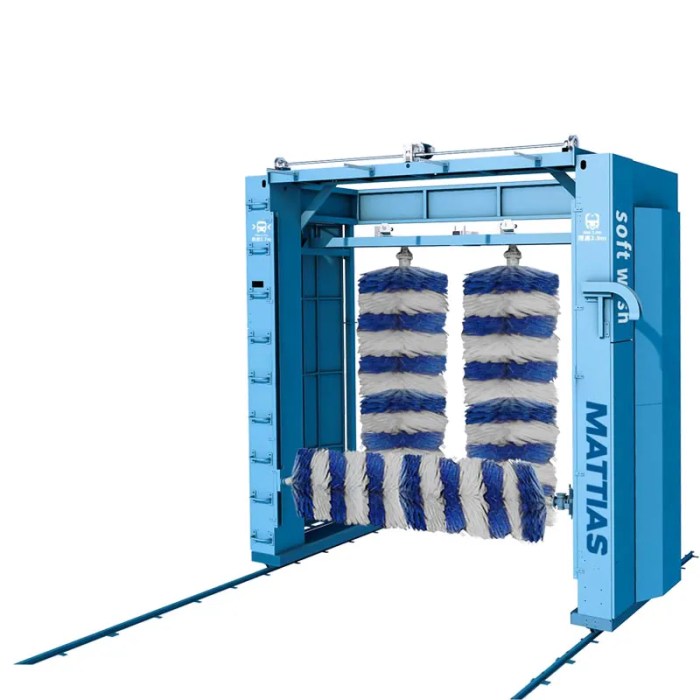

In-bay automatic car washes use a system of automated brushes, high-pressure nozzles, and chemical dispensers to clean vehicles. The vehicle remains stationary while the washing equipment moves around it.

| Equipment Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| In-Bay Automatic | Automated system where the washing equipment moves around a stationary vehicle. Typically includes pre-soak, wash, rinse, and drying cycles. | Consistent cleaning results; faster wash times compared to self-service; requires less labor. | Higher initial investment cost; potential for damage to vehicle finishes if not properly maintained; limited customization options for the wash process. |

Conveyor Systems

Conveyor systems are fully automated car washes where vehicles are moved through a series of washing stages on a conveyor belt. These systems are typically larger and more complex than in-bay automatics.

| Equipment Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Conveyor System | Fully automated system using a conveyor belt to move vehicles through a series of washing stages, including pre-soak, wash, rinse, and drying. Often incorporates advanced features like undercarriage washes and tire cleaners. | High throughput; consistent and efficient cleaning; can accommodate a wide range of vehicle sizes; potential for additional revenue streams through upselling options. | Highest initial investment cost; significant space requirements; complex maintenance needs; higher operational costs. |

Equipment Comparison: Cost and Maintenance

The initial investment cost varies significantly across these equipment types. Self-service bays represent the most affordable option, followed by in-bay automatics, with conveyor systems demanding the highest upfront investment. Operating expenses also differ; self-service bays have higher labor costs associated with cleaning and maintenance, while automated systems require less labor but necessitate regular maintenance and potentially more expensive parts replacements.

Conveyor systems, being the most complex, have the highest maintenance requirements and operational costs. For example, a small self-service operation might see an initial investment of $50,000-$100,000, while a large conveyor system could easily cost upwards of $500,000 or more. Maintenance costs are directly proportional to the complexity of the system. A simple self-service bay might require a few hundred dollars a month in maintenance, while a conveyor system could require thousands.

Key Components of Commercial Car Wash Systems

A commercial car wash operates as a finely-tuned machine, relying on the seamless integration of several key components to deliver a consistently efficient and high-quality wash. Understanding these components and their interactions is crucial for both operating and maintaining a successful car wash business. This section details the essential parts of a typical commercial car wash system and their roles in the overall process.

The efficiency and profitability of a commercial car wash are directly tied to the effectiveness of its core components. These components work together in a carefully orchestrated sequence to clean vehicles quickly and thoroughly, minimizing water and chemical usage while maximizing throughput. A breakdown of these components will illustrate their individual importance and interconnectedness.

Wash Bays

Wash bays are the heart of any commercial car wash operation. These bays house the machinery responsible for the actual cleaning process. They are typically designed for efficient vehicle flow, often incorporating conveyor systems or automated movements to minimize idle time. Different types of wash bays exist, from in-bay automatics with moving brushes and high-pressure nozzles to self-service bays equipped with various cleaning tools and detergents.

The design and configuration of the wash bay directly impact the capacity and speed of the car wash operation. Larger bays can accommodate larger vehicles, while multiple bays allow for higher throughput.

Dryers

Following the washing stage, efficient drying is crucial to prevent water spotting and ensure customer satisfaction. Commercial car washes utilize high-powered air dryers, often employing multiple blowers to quickly remove water from the vehicle’s surface. These dryers are designed to minimize drying time and prevent damage to the vehicle’s paint. The power and placement of these dryers are carefully considered to optimize drying efficiency and prevent water streaks.

Advanced systems may include forced-air drying combined with absorbent cloths or other technologies for enhanced results.

Chemical Dispensing Systems

Precise chemical dispensing is critical for maintaining consistent cleaning quality and minimizing chemical waste. Commercial car washes utilize automated chemical dispensing systems that accurately measure and mix detergents, soaps, and other cleaning agents. These systems often incorporate programmable controls to adjust chemical concentrations based on the wash cycle selected. Accurate dispensing not only ensures consistent cleaning but also helps control costs by preventing overuse of chemicals.

The systems typically include storage tanks for various chemicals, pumps for precise metering, and mixing chambers to ensure proper dilution.

Water Reclamation Systems

Water conservation is becoming increasingly important, and water reclamation systems play a significant role in reducing water consumption in commercial car washes. These systems treat wastewater from the wash process, removing solids and contaminants. The treated water can then be reused in the wash process, significantly reducing the overall water footprint. The efficiency of the reclamation system directly impacts the operational costs and environmental impact of the car wash.

Common methods include filtration, sedimentation, and sometimes advanced treatment processes to meet local water discharge regulations.

Diagram of Water and Chemical Flow

Imagine a simplified diagram. First, the vehicle enters the wash bay. The system then begins with a pre-soak phase where a mixture of water and detergent, precisely measured by the chemical dispensing system, is sprayed onto the vehicle to loosen dirt and grime. This pre-soak solution flows from a storage tank through the dispensing system, via pipes and nozzles, onto the vehicle.

Next, high-pressure water jets, often combined with specialized brushes or cloths, remove the loosened dirt. This wastewater is collected and sent to the water reclamation system. The reclaimed water, after filtration and treatment, is then reused in the pre-soak or rinse cycles. Finally, the vehicle moves to the drying stage, where high-velocity air from the dryers removes the remaining water.

The entire process is designed for efficient water usage and minimizes chemical consumption.

Maintenance and Repair of Commercial Car Wash Equipment

Keeping your commercial car wash equipment in top shape is crucial for maximizing profitability and minimizing downtime. Regular maintenance prevents costly repairs and ensures consistent, high-quality washes for your customers. Neglecting maintenance can lead to significant financial losses and reputational damage. This section details best practices for preventative maintenance, common problems and their solutions, and the importance of regular inspections.

Preventative Maintenance Schedule

Preventative maintenance is the cornerstone of a successful car wash operation. A well-structured maintenance program significantly extends the lifespan of your equipment and reduces the likelihood of unexpected breakdowns. The following table Artikels a sample preventative maintenance schedule. Remember to adapt this schedule to your specific equipment and usage patterns.

| Maintenance Task | Frequency | Procedure | Potential Issues |

|---|---|---|---|

| Inspect and clean all pumps | Weekly | Check for leaks, debris, and proper lubrication. Clean pump housings and filters. | Leaks, reduced flow, pump failure. |

| Check and lubricate all moving parts | Weekly | Apply appropriate lubricant to bearings, chains, and other moving components. | Increased friction, premature wear, component failure. |

| Inspect and clean conveyor belts | Weekly | Check for wear, tears, and proper alignment. Clean debris from the belt and surrounding areas. | Belt slippage, damage to vehicle, uneven wash. |

| Inspect and clean chemical injection systems | Monthly | Check for leaks, clogs, and proper chemical delivery. Clean injectors and lines. | Inconsistent chemical application, damage to vehicle finish. |

| Inspect and clean high-pressure nozzles | Monthly | Check for clogs and wear. Replace worn or damaged nozzles. | Uneven wash, reduced cleaning power. |

| Inspect and clean water filtration system | Monthly | Check for clogs and back pressure. Clean or replace filters as needed. | Reduced water flow, poor wash quality, damage to equipment. |

| Full system inspection and preventative maintenance | Quarterly | Thorough inspection of all components by a qualified technician. | Early detection of potential problems. |

Common Problems and Solutions

Several common problems plague commercial car wash equipment. Addressing these issues promptly prevents further damage and downtime.

For example, a common issue is clogged nozzles. This results in an uneven wash and reduces cleaning power. The solution is simple: regular cleaning and replacement of worn nozzles. Another frequent problem is conveyor belt issues, such as slippage or damage. Regular inspections, proper lubrication, and timely repairs prevent costly downtime.

Finally, pump malfunctions, often caused by debris or lack of lubrication, can lead to reduced water flow or complete system failure. Regular inspections and maintenance are key to avoiding these issues.

Importance of Regular Inspections and Qualified Technicians

Regular inspections are vital for identifying potential problems before they escalate into major repairs. Early detection of issues allows for timely intervention, preventing costly downtime and extending the lifespan of your equipment. Qualified technicians possess the expertise to perform thorough inspections, diagnose problems accurately, and implement effective solutions. Their knowledge ensures that repairs are done correctly, preventing further damage and ensuring the long-term performance of your car wash system.

Relying on qualified technicians is an investment in the longevity and efficiency of your business.

So, you’re thinking about investing in some serious commercial-grade car wash equipment? That’s a smart move, especially if you want to keep your ride spotless. But, to protect that investment, you might also want to check out some solid security, like the Top-rated dash cams with 4K night vision 2025 , to catch any potential incidents.

Then, once you’ve got your car looking and feeling its best, you can really appreciate the power of that top-of-the-line wash equipment!

Water Management and Environmental Considerations: Commercial-grade Car Wash Equipment

Operating a commercial car wash requires a significant amount of water, making responsible water management crucial for both economic and environmental reasons. Modern car washes are increasingly adopting sustainable practices to minimize their water footprint and reduce their impact on local ecosystems. This involves implementing innovative technologies and operational changes to conserve water and treat wastewater effectively.Water conservation in modern commercial car wash systems is paramount, driven by both environmental responsibility and cost savings.

High-efficiency equipment and water reclamation systems play a key role in reducing water usage.

Water Reclamation and Recycling Systems

Water reclamation and recycling are essential components of environmentally conscious car wash operations. These systems capture and filter wastewater, removing contaminants like soap, dirt, and oil. The treated water is then reused in the wash process, significantly reducing the overall water consumption. For example, a high-efficiency system might reuse up to 80% of the water used in a wash cycle, dramatically lowering the demand on municipal water supplies.

These systems often incorporate advanced filtration technologies, such as multi-stage filtration with sand filters, activated carbon filters, and ultraviolet (UV) disinfection to ensure the reclaimed water meets quality standards for reuse. The effectiveness of these systems is measured by the percentage of water recycled and the quality of the recycled water. A well-maintained system can significantly reduce water bills and minimize environmental impact.

Environmental Impact of Car Washes and Minimizing Ecological Footprint

Car washes, if not managed sustainably, can contribute to water pollution through the discharge of soapy wastewater containing detergents, chemicals, and sediment. This can harm aquatic life and ecosystems. Minimizing the ecological footprint involves several strategies, including the use of biodegradable cleaning agents, effective wastewater treatment, and responsible water management practices. Implementing water reclamation systems, as described above, is a critical step.

Additionally, using low-flow nozzles and high-pressure washing techniques can reduce water consumption without compromising cleaning effectiveness. Regular maintenance of equipment is also crucial to prevent leaks and ensure optimal water usage. Finally, promoting environmentally friendly practices, such as educating customers about the benefits of water conservation, can further reduce the environmental impact.

Water Treatment Methods in Commercial Car Washes

Several water treatment methods are employed in commercial car washes to reduce water consumption and pollution. These methods vary in complexity and effectiveness, depending on the specific needs and resources of the car wash. Common methods include: filtration (as discussed above), which removes solids and larger particles; chemical treatment, which neutralizes detergents and other chemicals; and UV disinfection, which kills harmful bacteria and viruses.

Some systems even incorporate advanced oxidation processes (AOPs) to break down organic pollutants. The choice of treatment method depends on factors such as the volume of wastewater generated, the type of cleaning agents used, and local environmental regulations. Effective water treatment significantly reduces the amount of pollutants discharged into the environment, protecting water bodies and ecosystems.

Choosing the Right Equipment for a Specific Business

Selecting the optimal commercial car wash equipment is crucial for profitability and efficiency. The right setup depends heavily on your specific business needs, encompassing factors like anticipated volume, available budget, and local environmental regulations. A poorly chosen system can lead to significant operational inefficiencies, increased maintenance costs, and ultimately, lower profits. This section Artikels a systematic approach to making informed equipment choices.

Factors Influencing Equipment Selection

Several key factors must be considered when choosing commercial car wash equipment. Ignoring these can lead to significant long-term problems. Careful analysis of these aspects is essential for a successful car wash operation.

- Business Size and Volume: A small, independent car wash will have vastly different equipment needs than a large, high-volume facility. A small operation might suffice with a single-bay, self-service setup, while a larger operation would require a multi-bay, conveyor system capable of handling a much higher throughput. For example, a small operation might only need a single soft-wash system, while a larger operation might require multiple systems, including a high-pressure system for pre-soaking.

- Budget: The available budget directly impacts the type and scale of equipment that can be purchased. A limited budget might necessitate opting for used equipment or a more basic system, while a larger budget allows for more advanced, high-capacity equipment. For instance, a larger budget could allow for the inclusion of advanced water recycling systems, reducing operating costs.

- Local Climate and Environmental Regulations: Harsh weather conditions (e.g., extreme cold or frequent rain) necessitate equipment designed for those conditions. Additionally, compliance with local environmental regulations concerning water usage and wastewater treatment is paramount. For example, a location with strict water restrictions might require a system with advanced water recycling capabilities.

Step-by-Step Guide to Equipment Selection

A structured approach is vital for making informed equipment decisions. Following these steps will help ensure that your chosen equipment aligns with your business goals and operational requirements.

- Assess Business Needs: Define your target customer base, anticipated volume, and service offerings (e.g., self-service, full-service, detailing). This will determine the required capacity and features of your equipment.

- Determine Budget: Establish a realistic budget encompassing equipment purchase, installation, maintenance, and ongoing operational costs. Consider financing options if necessary.

- Research Equipment Options: Investigate various equipment types from reputable manufacturers. Compare features, capacity, efficiency, and pricing. Consider both new and used equipment options.

- Consult with Experts: Seek advice from experienced car wash professionals or equipment suppliers. Their insights can be invaluable in making informed decisions.

- Evaluate Environmental Impact: Assess the environmental footprint of different equipment options, focusing on water consumption and wastewater treatment. Choose equipment that complies with local regulations and promotes sustainability.

- Analyze ROI: Calculate the return on investment (ROI) for different equipment options. Consider factors such as initial investment, operating costs, revenue generation, and equipment lifespan. This will help you identify the most financially viable option.

Return on Investment (ROI) Estimation

Accurately estimating ROI is crucial for justifying equipment purchases. This involves a careful assessment of all associated costs and potential revenue streams.

ROI = (Net Profit / Initial Investment) x 100%

For example, let’s consider two scenarios: a basic self-service bay costing $50,000 with projected annual net profit of $10,000, and a more advanced conveyor system costing $200,000 with projected annual net profit of $40,000. The basic system yields a 20% ROI (10,000/50,000 x 100%), while the conveyor system offers a 20% ROI (40,000/200,000 x 100%). While the ROIs are the same in this example, the higher-capacity system might be preferable for businesses aiming for higher volume and faster return of investment.

This is a simplified example; a more thorough analysis would incorporate factors like equipment lifespan, maintenance costs, and potential for increased pricing over time.

Safety Procedures and Regulations

Operating and maintaining commercial car wash equipment requires a strong commitment to safety. Failure to adhere to proper procedures can lead to serious injuries or equipment damage. This section Artikels crucial safety guidelines, potential hazards, and relevant regulations to ensure a safe and compliant car wash operation.

Safe operation of commercial car wash equipment hinges on preventative measures and a thorough understanding of potential risks. Proactive safety practices are paramount to minimizing accidents and ensuring the well-being of employees and customers.

Safety Guidelines for Operating and Maintaining Commercial Car Wash Equipment

Following these guidelines is essential for preventing accidents and ensuring a safe work environment. Regular training and reinforcement of these procedures are vital for all personnel.

So, you’re thinking about getting some serious commercial-grade car wash equipment for your detailing business? That’s awesome! But before you go all-in, maybe consider how you’ll keep your rig clean – especially if you’re planning some off-road adventures. Check out these Affordable lift kits for Jeep Wrangler 2025 to make sure your Jeep can handle whatever Mother Nature (or your detailing clients) throws at it.

Then, you can hit those washes with confidence knowing your investment is protected.

- Always disconnect power before performing any maintenance or repair work on electrical components.

- Use appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection, as needed.

- Regularly inspect equipment for wear and tear, ensuring all safety guards and interlocks are functioning correctly.

- Never operate equipment if it is malfunctioning or damaged. Report any issues immediately to a supervisor.

- Follow manufacturer’s instructions for operation and maintenance, including proper lubrication and cleaning procedures.

- Establish and enforce lockout/tagout procedures for electrical and mechanical equipment during maintenance.

- Provide regular safety training to all employees on the proper operation and maintenance of equipment.

- Implement a system for reporting and investigating all accidents and near misses.

- Ensure adequate lighting and ventilation in the car wash area.

- Maintain a clean and organized workspace to prevent trips and falls.

Potential Hazards and Risk Mitigation Measures

Several hazards are inherent in commercial car wash operations. Understanding these risks and implementing effective mitigation strategies are crucial for safety.

- Electrical Hazards: High-voltage equipment and wet environments create a significant risk of electric shock. Mitigation: Implement Ground Fault Circuit Interrupters (GFCIs), use insulated tools, and ensure proper grounding of all equipment.

- Mechanical Hazards: Moving parts, such as conveyor belts and brushes, pose a crushing or entanglement risk. Mitigation: Use appropriate safety guards, lockout/tagout procedures, and regular equipment inspections.

- Chemical Hazards: Detergents and cleaning solutions can cause skin irritation, eye damage, and respiratory problems. Mitigation: Provide proper training on handling chemicals, use appropriate PPE, and ensure adequate ventilation.

- Slip and Fall Hazards: Wet floors and spilled chemicals increase the risk of slips and falls. Mitigation: Use non-slip flooring, implement regular cleaning procedures, and provide adequate drainage.

- Noise Hazards: High-noise levels from equipment can lead to hearing loss. Mitigation: Provide hearing protection, implement noise reduction measures, and monitor noise levels regularly.

Relevant Safety Regulations and Compliance Requirements

Commercial car washes must comply with various safety regulations at the local, state, and federal levels. These regulations cover aspects like electrical safety, chemical handling, and workplace safety.

Compliance with OSHA (Occupational Safety and Health Administration) standards is crucial. Specific regulations will vary depending on location and the type of equipment used. It is essential to consult with relevant authorities and ensure all equipment meets safety standards and that all employees receive the necessary safety training. Regular inspections and maintenance are critical to ongoing compliance.

Technological Advancements in Commercial Car Wash Equipment

The commercial car wash industry is constantly evolving, driven by the need for increased efficiency, reduced environmental impact, and enhanced customer experience. Technological advancements are reshaping the landscape, offering innovative solutions that improve speed, quality, and sustainability. This section explores the latest innovations and compares them to traditional methods.Technological advancements have significantly improved the efficiency and effectiveness of commercial car wash systems.

Automated systems, touchless washing technologies, and advanced chemical dispensing systems are revolutionizing the industry, leading to improved throughput, reduced water and chemical consumption, and a better overall wash experience. These advancements represent a substantial shift from earlier, more labor-intensive and less environmentally friendly approaches.

Automated Car Wash Systems, Commercial-grade car wash equipment

Fully automated car wash systems represent a major leap forward. These systems utilize sophisticated sensors, robotic arms, and computer controls to guide the vehicle through the wash process with minimal human intervention. This automation increases throughput significantly, allowing for more vehicles to be processed in a given time period compared to traditional conveyor systems. The consistent application of wash chemicals and precise control of the washing process ensures a more uniform and effective clean.

A typical automated system might include a conveyor system that moves the vehicle through various stages, including pre-soaking, washing, rinsing, and drying, all controlled by a central computer. Modern systems even incorporate features like tire cleaning and undercarriage washes.

Touchless Car Wash Technology

Touchless car wash systems utilize high-pressure water jets and specialized cleaning chemicals to clean a vehicle without physical contact. This approach minimizes the risk of scratching the vehicle’s paint, a significant concern for many car owners. The technology often incorporates advanced sensors to adjust the water pressure and chemical application based on the vehicle’s size and type. While traditional car washes rely on brushes and cloths, which can potentially cause damage over time, touchless systems offer a gentler, more protective alternative.

However, they may not be as effective at removing stubborn dirt or grime compared to brush-based systems, especially in heavily soiled conditions.

Advanced Chemical Dispensing Technologies

Precise chemical dispensing is crucial for effective and efficient cleaning while minimizing environmental impact. Modern car washes utilize advanced systems that precisely measure and dispense the correct amount of cleaning chemicals, reducing waste and ensuring optimal cleaning performance. These systems often incorporate feedback mechanisms to adjust chemical usage based on factors like water hardness and soil level. This contrasts with older methods where chemicals were often manually mixed and dispensed, leading to inconsistencies and potential over-application.

Precise chemical dispensing not only improves the wash quality but also contributes to environmental sustainability by reducing chemical consumption.

Evolution of Commercial Car Wash Technology

Imagine a visual timeline starting with a simple, manual car wash in the early 20th century, depicted as a person with a bucket and sponge. The next stage shows the introduction of conveyor systems in the mid-20th century, depicted as a simple conveyor belt moving cars through a series of washing stations. The third stage illustrates the incorporation of automated washing equipment and more sophisticated chemical dispensing systems in the late 20th century, shown as a more complex system with robotic arms and computer controls.

Finally, the present-day stage showcases fully automated, touchless systems with advanced chemical dispensing and water recycling technologies, depicted as a streamlined, technologically advanced car wash with minimal human intervention. This visual representation highlights the significant advancements in efficiency, automation, and environmental consciousness over time.

Summary

So, there you have it – a comprehensive look at the world of commercial-grade car wash equipment. From understanding the different system types and their components to mastering maintenance and eco-conscious practices, you’re now equipped to make informed decisions. Whether you’re starting a new business or upgrading your existing setup, remember that choosing the right equipment is key to success and profitability.

Now go out there and make those cars sparkle!